Augmented Reality in mechanical- and plant-engineering

How the use of immersive technologies is changing the industry

In today’s digital world, Augmented Reality technology has a major impact on the way we work and live. The importance of AR has also increased in mechanical and plant engineering in recent years and opens up many new possibilities for companies. Whether it is a matter of training employees, improving the maintenance of machines and systems or making production more efficient, AR has many areas of application here.

Training without risk: How Augmented Reality makes employees fit to work with large systems

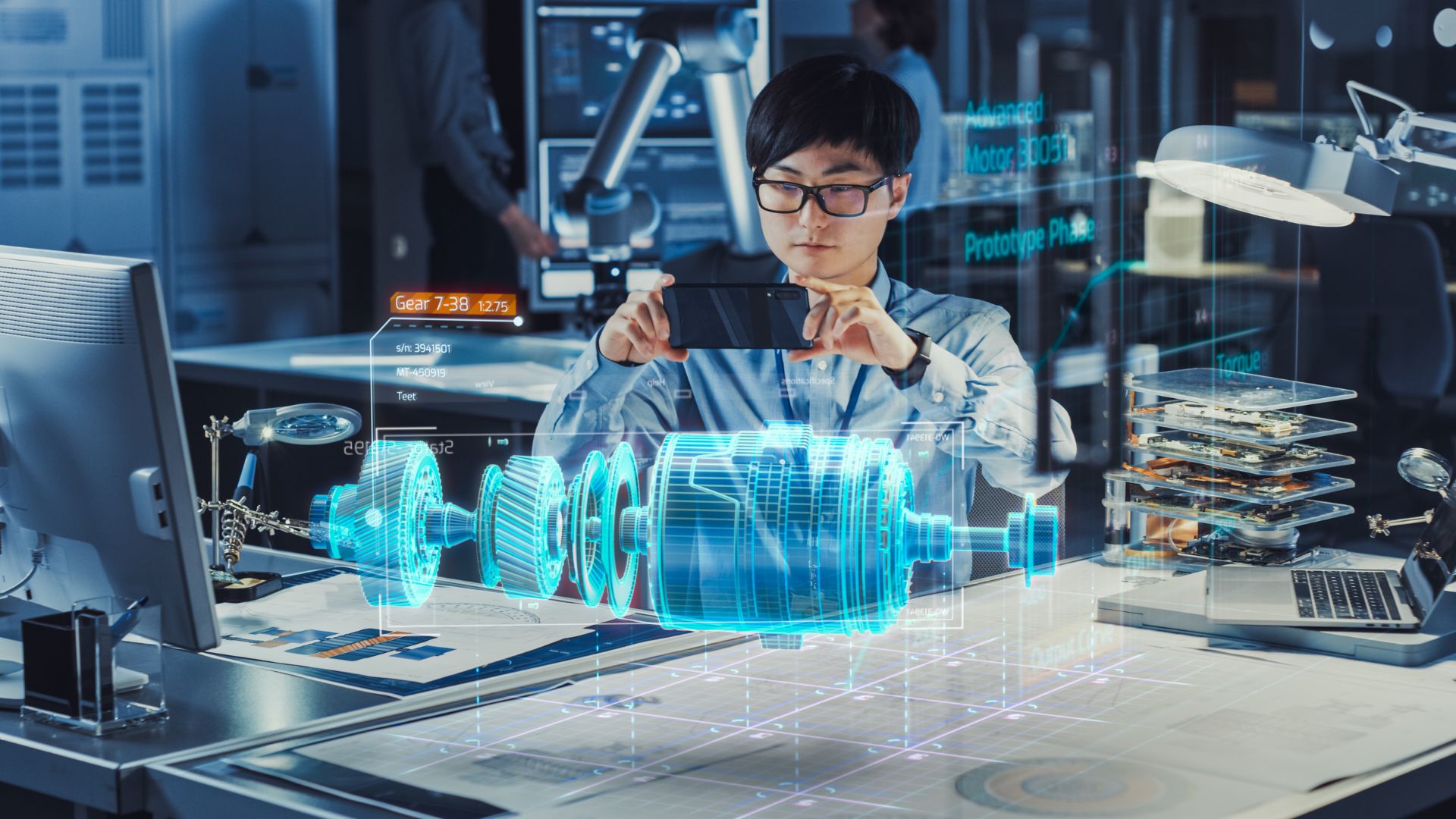

AR has many potential applications in mechanical and plant engineering, especially with regard to the training of employees in maintenance. Augmented reality makes it possible for trainees to train on virtual models of systems without actually coming into contact with them. The advantages of this are obvious – for one thing, the risk of injury is almost non-existent, and for another, they can try things out without damaging the equipment and thus causing it to fail. But AR can also be a very practical aid when working directly on the machine. During maintenance, for example, AR can be used to display the required information directly on the component in question, which increases the efficiency of the maintenance period.

But it’s not just employees who benefit from AR training: It can also make it easier to train customers by showing them how the equipment works directly and simply digitally, without having to stop it or even be on site. All it takes is a smartphone or tablet. Timeless, practical, innovative.

Production without AR? That’s like searching without Google!

The potential uses of AR are also very diverse in production. One example is the use of AR glasses. They enable employees to see steps of the assembly process directly in their field of vision and thus to work faster and more precisely. In addition to the operational benefits, the use of AR also pushes the collaboration of employees in production facilities. With the support of AR, information can be made available more quickly and easily. Problems are solved faster and the efficiency of the team is increased.

Airbus, for example, used Microsoft HoloLens to support aircraft production.

AR planning turbo for machines and plants

Always one step ahead: AR technology enables engineers and architects to work virtually on the design of large machines and plants before they are actually built. When communicating with customers and investors, realistic ideas of planned projects can be conveyed in advance to make decisions even easier. But it gets even better: turbines can be visually placed and aligned in their planned environment to ensure that the highest possible performance is achieved. This helps to identify and avoid potential problems in the planning phase before they lead to high costs.

AR Marketing: Mechanical and Plant Engineering Meets Reality Enhancement – Products Presented Like Never Before

Augmented Reality offers advantages in mechanical and plant engineering not only in terms of planning and maintenance of machines and plants, but also in the area of marketing. Companies can use AR to present their products in an exciting and interactive way by giving customers the opportunity to test them in realistic scenarios.

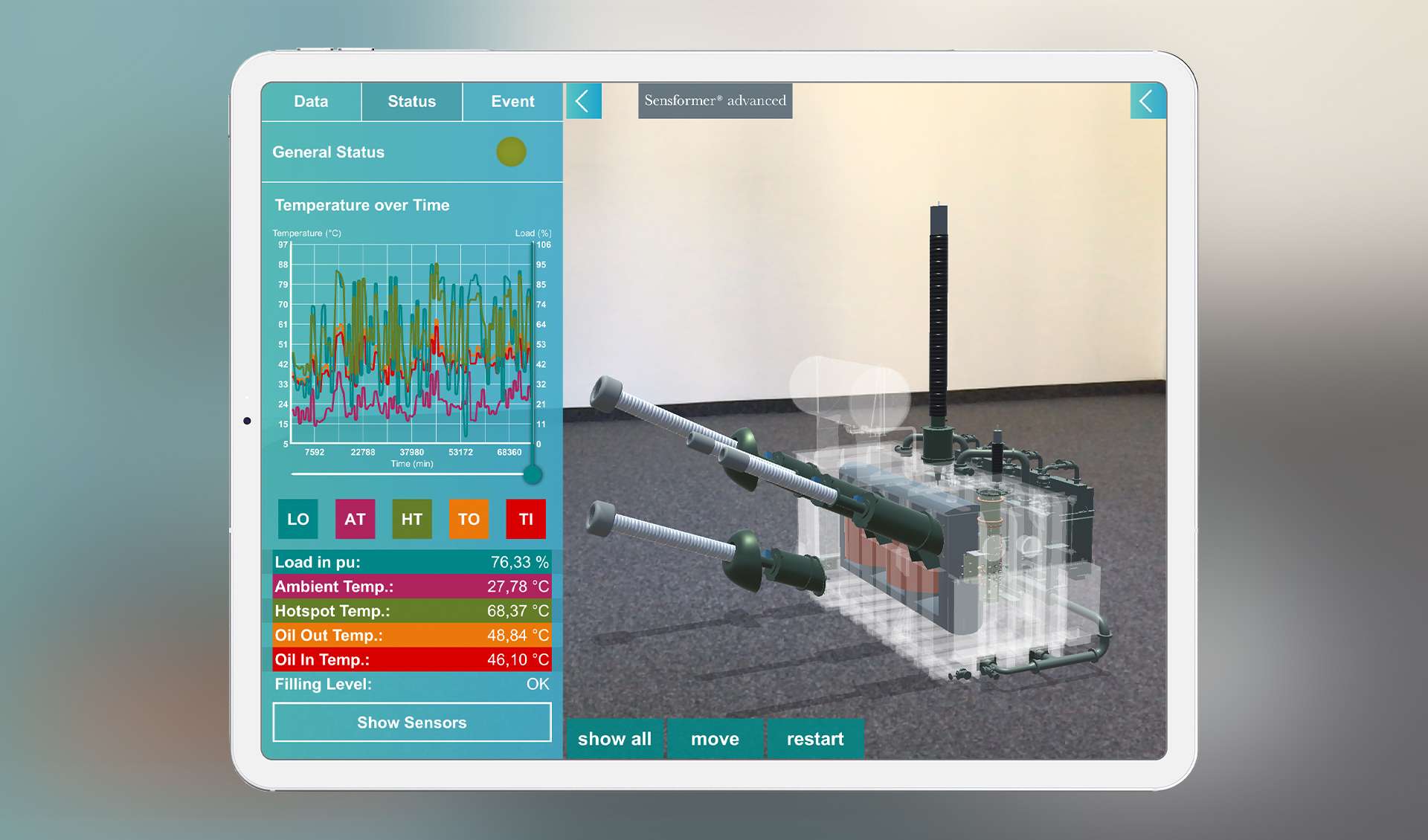

At trade fairs and exhibitions, AR offers the opportunity to present products in an impressive way by letting trade fair visitors experience the equipment immersively and giving them a picture of how they can use it in their own environment. Another great point is that large machines and systems can be presented without actually having to transport them – an example of this is the Siemens Sensformer, which was presented by Siemens in AR at Hannover Messe 2019.

Without having to bring the product from A to B, the power transformer from Siemens could be brought to the customer virtually and all its functions could be visualized easily. An X-ray view into the device also made it possible to get to know the technical details in more detail and to provide trade fair visitors with all the relevant information – without having the transformer physically on site. Who needs magic when you can have the right technology?

Want to learn more about Augmented Reality at trade shows?

Then click here.